In 1877, a group led by Peter Morgan discovered coal in this narrow canyon. However, since the exploration team had decided to travel in the early winter, they were caught in a blizzard and held there until the following February. Originally, the area was named Pleasant Valley, but because of the forced camp site the men decided to rename it Winter Quarters.

Not long after the discovery, Winter Quarters became one of the most impressive cities in the state. Houses dotted the valleys and canyons. The business district grew to be more than a mile long. The residents built many fine stone buildings which were just as impressive as some of those in Salt Lake City.

Through the years, many different nationalities lived at Winter Quarters. In the 1908 census, there were American-born citizens as well as German , Finnish , Swedish, Austrian, S1av, French, Italian, Creek, and Dutch immigrants listed as residents. There were 497 adults plus 338 others under the age of 21 (Sun Advocate 8).

Not only was the town striking, but the scenery in which it was set was breath-taking. Pine trees, quaking aspens, and wild vegetation surrounded the town. Wild raspberries even grew along the creek which ran all year round (Donaldson 182). The spring and summers were mild, green, and very beautiful, However, the winters were not so pleasant with their deep snows and cold wind.

Horses were a sign of summer's arrival because they were sent away every winter. The townspeople always celebrated the return of the horses to Winter Quarters. The residents sometimes built bowers with quaking aspen boughs in the forest beyond the town boundaries. Webster's New World Dictionary defines a bower as a place enclosed by overhanging boughs of trees or by vines on a trellis. Lunches were packed, ice cream was made, and the townspeople escaped to their retreat in the woods for this special summer celebration . Automobiles were another sign of summer because they, too, were only used in the "good weather" months.

In the winter a horse-drawn snowplow cleared the road for the company bobsled, and when the snow was deep the railroad tracks were used to walk to school, the grocery store, and church. The amusement hall played silent movies and hosted vaudeville shows for the residents to watch, This amusement hall was also the local lodge of the International Order of Odd Fellows. They used the hall for balls and community dances. It is ironic that one of the last dances planned for the hall was scheduled for May 1, 1900. It was to be held in honor of Dewey Day, which was also called May Day.

Winter Quarters mine Number One opened in 1878. Mules had to transport the coal at first because the railroad had not been laid through that area yet. In 1877-79, the Utah and Pleasant Valley Railroad replaced the mules' jobs in order to transport the coal more efficiently. The railroad ran from Springville to Winter Quarters and Scofield. Shortly afterwards, in 1882, Winter Quarters became a branch of the Denver and Rio Grande Western Railway.

The coal from this area was the region's highest quality coal. As many as 1800 people worked in the mines in different shifts at the peak of coal production. Winter Quarters mines Number One and Number Two were operated by the Pleasant Valley Coal Company. These two mines produced sixty percent of Utah's coal (Milan, Disaster 15). These mines also earned a reputation as being among the safest in the West. People were proud of this reputation because many lives had been lost during mine explosions in other areas.

The week preceding the explosion was a wonderful week for the residents. An important contract was signed. Two thousand tons of coal per day would need to be produced to meet the terms of the contract. This meant that the miners had the opportunity to work more frequently, and this meant more money. Not only were the families better off financially during that week, their health was on the rise. A quarantine flag which had plagued the community for some time finally came down, and the town was no longer threatened by small pox or the measles. The town's population was also on the rise and more buildings were constructed (Milan, Disaster 16).

On the surface, everything looked wonderful. However, a dark cloud loomed on the horizon, yet people chose to ignore signs of possible disaster. Despite warnings that had come forty days earlier, 368 miners entered the mine early May 1, 1900. Since they had a reputation for being the safest mine in the West, town residents did not place much stock in the warnings . If the warnings of possible explosions would have been noted more seriously, many lives could have been saved that fatal morning. A small fraction of the people in the mine that morning were sons of miners. The boys had come to work as couplers and trap boys. These boys connected coal cars and opened and closed doors inside the mine. Work preceded normally that morning and was well underway just minutes before the explosion. Some miners who survived reported that they felt something was not right that morning, but they continued work instead of acting on their premonitions.

At 10:28 a.m., a keg of powder was accidently ignited which caused a finely dispersed haze of coal dust to rise. The coal dust was ignited by errant sparks which exploded throughout the mine from room to room. The actual explosion promptly killed one hundred miners. Men were mutilated. One survivor described the scene as follows: "When a man was caught by the full force of the explosion, he was hurled against the wall or floor with the same effect that would follow the throwing of a piece of dough against the wall" (Milan, Explosion 17). Men were found with their hands raised to protect their faces. "Their eyes were closed and turned away from their hands indicating, perhaps, that the men saw the flash of the explosion" (Powell 28). All these men had apparently realized that death was coming.

Afterdamp, which is a mixture of toxic gases including methane, immediately followed the explosion. It spread through the mine fairly rapidly. Some could have escaped death if they would not have encountered this deadly gas, but the gas was very toxic. It brought instant death as miners inhaled the toxic fumes. They were frozen in time at the moment of death. One man was found filling his pipe. John James, a County Commissioner, was found with his son George "entwined in loving embrace in each other's arms" ("Most Appalling Mine Horror" Al). Others were found with tools in their hands or eating food. There were even groups of men gathered looking as though they were discussing what to do. Still others were overtaken as they tried to run ahead of the fumes, but they ran out of oxygen before they could escape.

Amazingly some survived, but the majority of those in the mine died a terrible death. Most of those who did survive sustained serious injuries. John Wilson, who was working near the mine, was blown eight hundred and twenty feet by the force of the explosion. The back of his skull was completely crushed, and a stick pierced through his abdomen. He recovered, but did not ever regain full strength. James Naylor, another miner, was thrown two hundred feet from the mine. Miraculously, though, he was uninjured and was able to aid in the first rescue attempts.

One of oddest stories was of Roderick Davis. He managed to escape from the mine after the explosion, but while aiding the rescue effort, he was overcome by the afterdamp and passed out. Thought to be dead, Davis was taken to a truck transporting corpses. The truck took the bodies to a building where he was placed in a row to be washed. "When the men began to wash him, he regained consciousness and walked out of the room" (Powell 29).

The removal of the bodies began at twelve o'clock. This first rescue party was headed by Bishop Parmley. They tried to enter mine Number Four through the Number One entrance, but as soon as they entered the mine afterdamp would overcome them. The rescue attempt could not continue until there was a clearing of the afterdamp and fresh air began to circulate through the mine. "After clearing away the fallen and dead horses at the mouth of the mine, they entered about two hundred yards when they came upon the dead bodies of six of the men" (Most Appalling Mine Horror" Al). The people in the rescue teams struggled to retrieve miners. About ten people were initially recovered when the rescuers were finally able to enter the mine. The first man to be removed from the mine was John Kirton. His whole scalp had been burned and his face was unrecognizable. Although he was in a fragile condition, he was still conscious and "cried out in agony for his fellow comrades to end his misery by killing him on the spot" ("Most Appalling Mine Horror" Al) After that rescuers tried time and time again to retrieve more bodies, but the lack of oxygen and horrible stench of burnt bodies was overpowering. As a result, many could no longer aid in rescue attempts. Rescuers were also in a state of severe emotional shock because of the realization that the dead were friends and family. Those who were able to act were concerned about the slow progress they were making and feared that bodies would be buried making total recovery very difficult. After spending sixteen hours coming in and out of the mine, physical and emotional exhaustion became too hard to bear. Finally, the first rescue team was able to rest when additional help arrived. Miners from Clear Creek, Castle Gate, and Sunnyside divided into rescue parties. As fast as one team was tired or worn out, others would hurry and take their places.

Although there were many miracles, the amount of death overwhelmed the town. It was a scene that made many strong men turn away in tears. The Salt Lake Tribune published the following statement: "The calamity was of such a size and so unprecedented in the history of the State, and even of the West, that the mind did not seem to be able to fully grasp it...for the families who would be deprived of husbands and brothers and other relatives, the blow came home with crushing force" (Al). Indeed, this was a tragedy that would take the town years to even begin to recover from. Some never recovered from their losses.

As bodies were found, trucks transported them to the boarding house, church, school, and barns to be received and identified. Women and children had to take care of the dead. A victim's clothes were removed first. Then the bodies were washed so they could more easily be identified. Tags were placed on them. A victim's family and friends would then more thoroughly wash the corpse, groom it, and dress the body. Only 137 of the bodies were identified. Suits were purchased for the victims by the Pleasant Valley Coal Company from Z.C.M.I. The company donated these burial suits to the victims. The L.D.S. church provided burial clothing for its members killed in the explosion.

Every casket in Salt Lake City was purchased, and an additional seventy-five were ordered from Denver. One hundred and fifty of those who died were buried in the Scofield Cemetery in the northwest corner on May 5, 1900. The local sawmill operator J.H. Eccles made headboards for the identified bodies. The names were each inscribed with a lead pencil. However, fifty percent of the names were spelled wrong and had to be corrected by friends or family members. The bodies that were not identified were buried in a mass grave in the Scofield cemetery.

Two burial services were held. One was performed by a Finnish Lutheran minister in honor of the sixty-two Finnish miners. Another was performed under the direction of Mormon apostles in memory of all those who had died. Fifty bodies were not buried in the Scofield cemetery. Instead, they were taken by two funeral trains to various places in Utah and the surrounding states (Powell 30).

The town was in a state of shock. The actual explosion had lasted less than a second, but it killed 199 miners leaving 105 widows and 270 fatherless children. This horrible tragedy changed the town forever. Life did go on, but people could, not forget what had happened. The mines continued operating until 1928 despite the sorrow that lingered. The quality coal from the mines declined until it eventually became suitable only for inexpensive locomotive fuel. Finally, the underground transporting costs doomed the mines because the profit from the coal sales was insufficient to pay the bills. People moved from Winter Quarters to Scofield. By 1930, Winters Quarters was vacant. Writer Morgan Donaldson wrote "Although the electricity was cut off and boards placed over the windows of the homes, our family continued to live there for several months. We could not believe that Winter Quarters had come to an end."

Now all that remains of this town are caved-in cellars and broken foundations. The ruins of a large stone store built by Italians masons is one of the most intact historical markers. The legend of Winter Quarters still lives on, though. "Of interest to treasure hunters is the fact that many of those killed at Winter Quarters were bachelor miners. No doubt many of them had secret post-hole banks near their cabins. Over the years, others were killed or died there, and many of them hid money they never recovered. When the town was abandoned, who knows how many other caches were left behind, unknown, forgotten, lost or buried by someone no 1onger able to recover them? They are the lost treasures of Winter Quarters today" (Thompson 96).

Works Cited

"Bower." Webster's New World Dictionary: Second College Edition. 1970.

Carr, Stephen L. Utah Ghost Towns. Salt Lake City, Utah: Western Epics, 1972.

Cunningham, Frances. Driving Tour Guide: Selected Abandoned Coal Mine Sites. Price, Utah: Peczuh Printing Company, 1990.

Carbon County Journal. Price, Utah: Carbon County Historical Society, 1980.

Dilley, J. W. Utah: History of the Scofield Mine Disaster. Knights of Pythias, 1900.

Donaldson, Waiter Morgan. "Winter Quarters." Legends of Carbon and Emery Counties. Price, Utah: Castle Country Chapter of the League of Utah Writers, 1996,

Milan, Noel. "Winter Quarters Disaster: The Day 200 Miners Died." Mine Safety and Health Oct. 1981: 15-19

"Winter Quarters Explosion - Part 2: The Disaster in 1900 that Killed 200." Mine Safety and Health Jan. 1982: 15-20.

"Most Appalling Mine Horror!" The Salt Lake Tribune 2 May 1900, morning ed. Al+.

Powell, Allan Kent. The Next Time We Strike

"Scofield Mine Disaster." Sun Advocate 27 June 1979: 1+.

Thompson, George A. Some Dreams Die: Utah's Ghost Towns and Lost Treasures. Salt Lake City: Dream Garden Press, 1982.

Watt, Ronald G. A History of Carbon County. Salt Lake City, Utah: Utah State Historical Society, 1997.

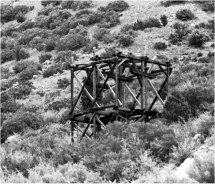

Rock Asphalt Plant

At the Sunnyside Jct. just off Highway 6 stands a monument erected by the Matt Warner Chapter 1900, E. Clampus Vitus, dedicated July 10, 1993. This monument tells about the Rock Asphalt plant. It says:

Rock asphalt was first mined at the top of Whitmore Canyon 15 miles NE of this location in the early 1890's. The mine closed in 1898 and reopened in 1903. It operated erratically until 1915 when it was forced to close due to the development of sheet asphalt. In 1927 another company tried to develop a rock asphalt industry. They spent over 1/2 million dollars on equipment including a 3 1/2 mile gravity powered aerial tramway. To promote the use of rock asphalt for paving, it was sold for $8.00 / ton even though production costs exceeded $16.00 / ton. This company went bankrupt in 1931 and the Rock Asphalt Company of Utah took over in 1932. The mine operated only about two months out of the year and eventually closed. Interest was rekindled in the 1970's but nothing ever developed.

Huge Rock Asphalt Deposits over at Sunnyside in Limelight

The Sun - Feb 24, 1928

PUEBLO, Colo., Feb. 18 - Ownership of what is believed to be the largest deposit of rock asphalt in the world has been secured by a company being organized here and at the head of which are C.N. Power, president; John F. Cregan, vice; Ben Bergerman, its secretary; Dr. Herbert A. Black, treasurer, and Andrew McGovern, Jr., the other member of the board of directors. The company is to be known as the Utah Rock Asphalt corporation. There are two series of shares - common and the preferred. Ownership of what is believed to be the largest deposit of rock asphalt in the world has been secured. It is located thirty-three miles east of Price, and is the third deposit of its kind known to exist in this country. The enterprise, directors of the new company believe, promises soon to develop into one of the largest industries of the West, comparable perhaps to the property of the Utah Copper company at Bingham. When crushed and meshed, rock asphalt in the opinion of highway engineers, makes the finest road surfacing material in present use. It has been preferred for many decades in Europe, where small deposits have been discovered and opened, and is approved in the United States as a standard road surfacing material by the federal highway commission in some thirty states. Engineers estimate that the Utah deposit contains enough material to surface one hundred thousand miles of highways twenty feet in width. A.B. Christy and John P. Hutchinson, who acquired an option on this property two and a half years ago, will be associated with the company as sales managers. A complete statement just issued by Power says:

Is Highly Impregnated

"The Utah Rock Asphalt corporation is a company organized under the laws of Colorado for the purpose of taking over and developing a deposit of rock asphalt located at Sunnyside, Carbon county, Utah. Rock asphalt is sandstone impregnated with bitumen just as some shales in Western Colorado are with petroleum. It is used as a road surfacing material. The quantity of rock asphalt is this deposit is practically unlimited. There is a whole mountain of it with no overburden. The estimate of the minimum quantity easily available is five hundred million tons. The engineers estimate that the amount is sufficient to keep the quarry in continuous opertion for a lifetime and to produce enough tonnage to provide surfacing for a hundred thousand miles of streets or roads. The Utah deposit is four hundred feet in depth and at least two miles in length. The next largest vein in this country, located in Kentucky, has a depth varing from five to twenty five feet. This latter deposit, according to officers of the company, is worked at a disadvantage through lack of transportaion facilities, though in spite of handicaps it markets five hundred thousand tons of rock asphalt a year. The Utah deposit, on the contrary, is located within five miles of a spur of the Denver and Rio Grande Western. Competent surveying engineers estimate that the Utah vein contains between two hundred and thirty five million and a billion tons of the material. It has a present market value of from five to six dollars a ton at the mine.

Machinery is Coming

Mining equipment and machinery for the preparation of the rock will be installed as soon as possible and actual quarrying will begin in April. Contracts have been assured which will consume the production of the company for the first year of operation. The rock is prepared at the quarry by crushing and washing it through a quarter inch screen. No further preparation is necessary of its use as a road surfacing material. When laid two and a half inches thick it compresses to one and five eights inches and becomes solid sandstone, which is practically indestructible. Under pressure it has the peculiar property of returning to the hard rock state. Highways upon which the material is used can be opened to traffic a few hours after rolling. This type of paving has several important advantages over any other, experiments in this country and abroad have shown. Because the rock is prepared in nature's laboratories over centuries of time the asphalt content is not affected by temperature changes. "Running" "rutting" and "bleeding," so common to asphalt in present general use are impossible, and hot and cold temperatures do not cause it to crack as in the use of concrete. The wear of continued use is almost negligible, engineers state.

Further advantage results from the ease with which the material can be laid. Requiring no prepartion for use it makes possible a saving in initial road costs of from 20 to 40 per cent. Maintenance appropriations can be substantially reduced as the surface is less affected by traffic than that of any other type of material. A number of highway engineers have asserted that rock asphalt will replace other materials for such purposes, although concrete will continue in use as a base. It is now in general use in Europe, where the supply is limited. The largest deposit over there is in Switzerland. The rock in the natural state is black, similar in texture to a hard form of sandstone. when meshed and prepared for use it appears as a black substance not unlike the asphalt now commonly in use on city streets. After being rolled and caused to reknit it assumes certain of its rock properties, but is somewhat more resilient.

Utah's Asphalt Production Process

Is One of Country's Most Interesting

Sun Advocate - October 9, 1947

Every story of western mining carries with it a hint of romanticism and the spirit of adventure that cannot be found in any other industry in the world. The history of brave men with visions of the good that can be derived from the hidden treasures of nature has always been and probably will continue to be a source of inspiration to those whose walks of life have carried them into the other fields of endeavor. There is something of a mystery about mining, whether underground or above, and one can't help but wonder at the strength of those who planned the industry into what it is today.

Utah's position as one of the leading states in the production of minerals is well know. Within its borders are found nearly every mineral of commercial importance. They hydrocarbon deposits of eastern Utah are enormous. Gilsonite and elaterite mines have been developed to a large extent and the products have been shipped to many parts of the world. Some of these hydrocarbons are perculiar, in that Utah is the only place in the world known where they are found.

Among the many natural resources Utah has within its borders is the deposit of rock asphalt found east of Sunnyside. This deposit is the largest and richest of natural rock asphalt in the United States and, perhaps, in the world. There are many deposits of rock asphalt within the United States and several plants are now processing large tonnage from those deposits for use in street and road constuction.

The Utah deposit which is owned by the Rock Asphalt company of Utah is estimated to contain some 800 million tons. It is estimated that the deposit contains enough rock asphalt to build three 64 foot roads completely encircling the globe.

The Sunnyside quarry is probably one of the most interesting in the country. Located 9,040 feet above sea level, the mineral is scooped out of the side of the mountain by huge shovels and is transported to the crushers in the valley eight miles away by means of huge buckets suspended on cables. The mountain in which the deposit is located is 10,000 feet high thus placing the diggings almost to the top. A private road leads to the mine winding up the mountain side and from there continues to top where, incidentally, is a deer hunter's paradise.

To have transported all of the heavy machinery to the quarry on the narrow road is an engineering fete within itself and is a source of wonder to the visitor.

Approximately 200 tons of rock asphalt are produced each nine hour working day from the present opening which ranges in thickness from 40 to 70 feet. Work is now going on to open a new face which is located several feet higher than the present working and which will open a vein ranging in thickness for 70 to 200 feet. The new section will also provide a much richer product. Initial tests have shown it to run at a minimum of 13 per cent bitumen. State specifications call for from 10 to 13 per cent bitumen with less than five per cent moisture content.

To obtain the asphalt, holes are drilled in the face and powder is used to blast the mineral loose. It is then loaded into trucks for transportation to the dump where it is picked up by the buckets which carry it down the canyon. The cable carrying the buckets is approximately 14 miles in length, seven miles of carrying cable and seven miles of track cable. Sixty three buckets are in use with the loaded buckets pulling the empties back to the mine. Each bucket carries 1200 pounds of asphalt and the round trip for each bucket takes 1 1/2 hours.

The mineral goes through a primary crusher before entering the buckets and is dumped into a storage bin at the bottom of the canyon. From here it is transported by trucks to the crusher at Sunnyside there it goes through two different sets of rolling mills before going through the final crushing process in a hammer mill. When the process has been completed the asphalt comes out of the mill in the form of powder as fine as flour. At this point it is loaded into railroad cars and trucks for distribution throughout the country. Each shipment is tested prior to distribution.

According to Eugene Pressett, superintendent of the Sunnyside operations, experiments are now being carried on by adding an oil emulsion to the crushed asphalt to develop a product that will withstand the lowest temperatures.

Rock asphalt, or bituminous sandstone as it is commercially known, is a mixture of asphalt and sand compressed by nature into hard rock which was formed by liquid oil, with an asphalt base, accumulating underground in some kind of geological trap. The sand which was originally laid down as a marine sand of fine and uniform texture was then covered in this manner by a pool of asphaltic base oil, which, due to extreme underground heat and pressure, allowed the bolatile matter to escape leaving a residue of pure asphaltum permeating this stratum of marine sand. This was followed by additional natural formative pressure which caused the sand to be completely permeated by and coated with asphalt to an average of about 10 per cent asphaltum and 90 percent pure silics sand. These sand particles are not merely suspended in the asphalt but every void and pore of the sand is permeated with asphaltum so that a complete breakdown of one grain of sand would give an assay comparable to a larger or average piece of rock asphalt.

Rock asphalt roads have been in use for many years. In fact, the first paved roads built in the world were of rock asphalt. History reports Paris built its first paved road of this material in 1854. The first paved street in the United States was built in 1872 in Union Square, New York City, of rock asphalt brought from Switzerland. The first street paved in Utah was old Commercial street in Salt Lake City and this was built in 1891 with rock asphalt brought from Santa Cruz, California. This started the development of the Utah deposits and in 1892 Richard street in Salt Lake City was paved with Utah rock asphalt and has been in continuous use for 17 years. The history of rock asphalt shows that it is the oldest known paving material and has been in continuous use since 1854.

At the present time, work is being completed on the laying of asphalt on every street in Dragerton including the driveways into every yard. Approximately 8000 tons of the material has been used on this project.

Production at the Sunnyside quarry is expected to close for this year on November 1 and during the winter months work is continued on stripping the earth and rock from off the top of the asphalt deposits to make ready for the next summer's production schedule. During the peak of the summer season 120 men are employed. At the present time only 35 are on the job. During the peak of the season, the payroll is some $25,000. per month. The workers are affiliated with the CIO Local No. 401, and Albert Leote, Price, is president.

Some of the men employed at the workings travel back and forth each day from Price while the others live in quarters clinging to the mountain side amidst mountain scenery that is a spectacle to view.

Photos donated by Don Butler.

Other articles about the Rock Asphalt plant

Sunnyside Memories pages 21 -26 - by Paul Turner

Utah Rock Asphalt - by G. Farlaino

Rock Asphalt Quarry / Tramway Operations -

by James E. Taylor, Aug. 2001 Carbon County Historical Quarterly

Ceremony for Laying of City Auditorium Cornerstone Today

Sun Advocate - Thursday, April 7, 1938

Sun Advocate - Thursday, April 7, 1938

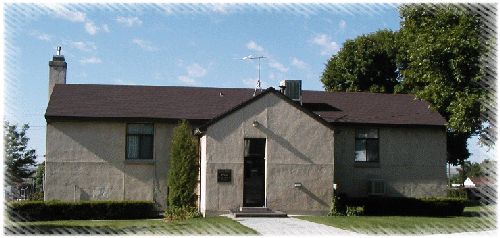

The cornerstone of the Price Municipal building will be laid in place this afternoon as the climax of a ceremony in observance of another step in the development of this community. A half haliday has been proclaimed by Mayor J. Bracken Lee in honor of the occasion.

Arthur W. Horsley, trustee on the town board in 1895 when the old city building was erected, will be one of the principal speakers. Mr. Horsley superintended construction of the $5,000 hall, and it was he who laid the first brick in the foundation the the last brick on the chimney. he also removed the first brick when the building was razed last fall to make way for the $150,000 structure.

The other principal speaker will be R.A. Hart, who was state manager of the P.W.A. at the time that the federal grant of $67,500 for the building was approved. Major Lee will be master of ceremonies.

Representatives of various church, civic, governmental and social organizations have been invited to attend and take part. The Price Elks' lodge will conduct the ritualistic ceremony which is designed for such occasions. The officers to participate are: Erin H. Leonard, exalted ruler; William M. Davis, esteemed leading knight; Nick Bernardi, esteemed loyal knight; Silas W. Anders, lecturing knight; Eugene Coli, treasurer; Maurice Tatton, Tyler; and S.J. Sweetring, secretary and acting chaplain in the absence of the Reverend R.C. Jones.

And important part of the ceremony will be the placing of documents in a copper box to be deposited in the cornerstone. Copies of newspapers relating to the building's construction, pictures of civic importance, possibly an ordinance book, and other items will be placed in the box, according to William Grogan, city recorder.

Music for the program will be furnished by the Carbon High School band, under direction of E.M. Williams.

Past, present brought together

by forgotten time capsule

by forgotten time capsule

Price cornerstone hides forgotten history capsule

By Jackie Anderson

Staff reporter

Sun Advocate - Thursday, April 1, 1999

By Jackie Anderson

Staff reporter

Sun Advocate - Thursday, April 1, 1999

Price continues to be the cornerstone in the lives of former residents throughout the country.

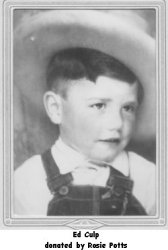

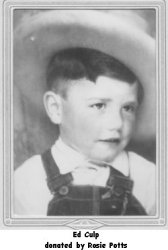

In 1938 Ed Culp was a 10 year old student at Harding Elementary. He is now 70 years old, in poor health and living in Vancouver, Washington.

His daughter, Rosie Potts, has been trying to clear up some of the unanswered details and questions in her father's life, one of which concerns a forgotten time capsule sealed in the cornerstone of the Price City Hall.

In an effort to assist her father, Potts contacted Lennis Anderson at the state library, who started the ball rolling, and Vern Jones at the city hall who "has picked it up and run with it."

Jones located several back issues of the 1938 Sun Advocate which contained articles regarding the laying of the cornerstone of the civic building."

The April 7, 1938 issue stated:

A number of documents were placed in a copper box and deposited in the cornerstone, these included the names of about 200 persons who were present at the ceremonies.

Other documents were: 1924 revised ordinances and history of Price; three issues of The Sun Advocate relating to the new building; notice of the bond election for the building; offer of the P.W.A. for the federal grant and notice of acceptance by the city; agreement with the contractors, Fausett and Presseto; financial statement of the city for 1937 and budget for 1938; pictures of persons and scenes relating to the history of Price; histories written by Abe Powell, Ernest Horsley and A.E. Gibson; list of officers of local organizations, two sales tokens; one copper cent; bank statements of the to local banks; Golden Jubilee Souvenir of Price ward, 1932; and telegrams of congratulations from Utah's national congressmen and senators.

Jones and city water crewmen explored a crawl space at the cornerstone after being contacted by Potts, but were unable to detect anything. A consecutive search with a metal detector proved more lucrative as they were definitely able to detect something magnetic.

"I am going to be contacting ABC News and various other media in an attempt to convince whoever needs to be convinced that this time capsule whould be opened! Governor Leavitt has been kept aware of the progress concerning the time capsule and Wayne Saltzgiver, who is the governor's assistant, will be bringing this up when he goes to Price. I just want to see this opened before my father dies." stressed Potts.

"He can remember that day so well," Potts stated regarding the laying of the cornerstone. "There is a paper in the time capsule which he signed his name to, as did the rest of the students in his class."

Culp last visited Price in 1953, and passing the courthouse several times, he wondered about the time capsule. "He could not imagine what it would be like to wait 50 years to open the time capsule, and now it has been 60." exclaimed Potts.

"There is no way to remove the capsule without demolishing the building, but it is important to be reminded in a permanent way that it is there so that if the building is destroyed in the future, people will be aware of the history that is hidden there." commented Jones.

Ed Culp

|  |

A portrait of Ed Culp as a young child. Culp was one of 200 who signed the register of the ceremony celebrating the laying of the City Hall cornerstone. Ed Culp was the grandson of George Washington Culp and Betsy Jane Powell. Betsy Jane Powell was the first white child born in Carbon County. |

|

|

|

| Pictured here is George Washington Culp and Betsy Jane Powell the grandparents of Ed Culp. | The headstone of Betsy Jane Powell is pictured at the left. Betsy Jane Powell Culp, George Washington Culp, Robert Powell and Rachel Powell are all buried in the Carbonville cemetery. |

|

1940 Price Junior High School Fifth Grade Buckaroos First row: Lila Lee Wilson, Joyce Ann Bench, Helen Peirce, Jacqueline King, Iris Andreen, Mary Kinoshita, Lenna Beth Rich Second row: Colleen Atwood, Jeanine Gilligan, Shirley Davis, Louise Hardy, Margie McIntire, Wanda Day, Hope Mortensen, Vera Leonakis, Miss Marion Robbins Third row: Ronald Wilden, Billy Gentry, Duane McPhie, Jimmie Kakatsidas, Darrell Culp, Lester Brinley, Bert Shiner, Bobbie McCarrie, Max Watkins Fourth row: Odell Anderson, Clyde Grames, Val Johnson, LaMar Olson, Bennie Christiansen, Jimmie Alger |

|

In 1940 Ed (Darrell) Culp attended the Price Junior High School and was in the fifth grade. His teacher was Miss Marion Robbins and as a 12 year old he had a crush on his teacher. He thought she was "quite a dish!!!". He said she had the most beautiful singing voice. She taught the class a song and he said when she sang it, it would give him a lump in his throat each time. He said that all thru his life when he would think about it, he would go right back to his fifth grade class and could hear her voice singing that song. In June of 2000, sixty years later, he was still able to remember the words of the song and recorded them: Oh, tell me Mother Meadow Lark, What sorrow fills your breast, You chirp and cry so pitiously, while searching thru your nest, your kids are gone, your life is runied, I feel so sorry for you, tell me mother meadowlark what, are you going to do, my babie's are gone I don't know where, To find them I don't know where to start, this thing is so upsetting it has really broke my heart, is someone going to feed my babies, will someone shelter them by night, I wish this was a dream then I could wake up and my babies will be all right. |

|

If you are related to this family or would like to join in the effort to have the time capsule opened please e-mail Rosie Potts.

Early history and beginning of the Price Branch Genealogy Library are vague and undocumented. Some "old timers" remember it began in a northwest room of the present bishops store house located on 100 South and 300 East. It is surmised the library was established during the 1950's or early 1960's with the storekeeper, Frank Hartley, being assigned to organize the library and get things started.

In 1964 Lorin Bailey and Glen Fifield were called to serve as directors. Brother Bailey served until 1975. During those eleven years, the Church Genealogy Department sent out research guides and began rental programs. Brother Bailey and Brother Fifield acquired two old microfilm readers, some old microfiche readers, a film cabinet, and some bookcases. All work was done by hand.

During this time the library was moved from the storehouse to the seminary building. Grant Lee Hanson and his wife, Bessie, were next called to direct the library. Carbon, North Carbon, and Emery Stakes were all involved. Librarians were called from each stake in order to keep the operation open all day and into the evening. This necessitated having thirty-nine people actively working at the library per week.

The Hansons spent their nine years improving all aspects of the library. Because of Brother Hanson's knowledge of the Danish language and his familiarity with the Scandinavian countries, he organized a very useful collection of genealogy books and materials for that region. The four generation program was intruduced during this time.

There were 333 microfilms and microfiche on permanent loan at the library in 1976. Many more were added to the collections as time went on. Books, periodicals, and research guides, along with readers and other equipment, became more available, partly due to the generous donations made by members of the three stakes.

Lynn Bennett served as director in 1984. Because trained librarians were hard to find and keep, Brother Bennett and others often spent forty to fifty hours per week keeping the library open and operational.

A new up-to-date computer that would run the Church's new "Family Search" program, and the newly developed Personal Ancestral File, was purchased during this tenure. People could now access information from all around the world. Brother Bennett also headed a project to collect all the obituaries from Utah daily newspapers from 1940 to 1985. He gathered over 187,000 obituaries that were filmed, indexed, and made available to every library in the world.

The Home Extraction Program had been operational for several years by this time. Many of the librarians became involved in this work.

In 1993 Carl Larsen became director. New computers, software, books, and genealogy information were constantly being added. A database of cemeteries in Carbon and Emery counties provided even more information. All of this required increased training and awareness for both the staff and patrons as they learned to overcome fears of technology.

James L. Jensen of the Price North Stake became the director in October of 1997. The name was changed from the Price Branch to the Price Family History Center. By this time only the Price Utah, Price Utah North, and Helper Stakes were using the facility as a multi-stake entity.

The rapid development of technology kept the center involved with constant efforts to stay current with changes in internet capabilities. New computers and printers were in constant demand. New programs were being developed daily.

The Center underwent another remodeling project in 1997. Five new computers were purchased along with two new printers. This made it possible to place a new computer at each of the eight stations. This revolutionized the center. Patrons now had billions of names at their finger tips. Research became an art requiring constant surveillance by the librarians.

As of January 2003, Levon and Mona Grundvig are serving as directors of the Price Family History Center.

During the tunure of each director, a new level has been reached for the output at the library. From its humble beginnings in the corner of the storehouse with the storehouse keeper as the consultant to a well-established technological project with full-time trained librarians, the Price Family History Center fills a powerful purpose for the Saints in Carbon County as they seek to fulfill the commandment of searching for their roots. This page is dedicated to Clark Hunt. It was his enthusiam and memories of the ski trail that made this page happen. A special thanks to Lori Perez of the Helper Mining and Railroad Museum for searching for the articles in the Sun Advocate newspaper.

History of Price Family History Center & Library

by James L. Jensen

Skiers Begin Work on Clear Creek Trail

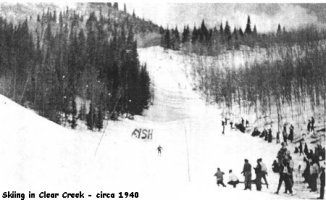

Fired by plans to make a newly selected site at Clear Creek, one of the best ski spots in the state, about fifteen of the more ardent enthusiasts of the sliding slabs spent last Sunday swinging axes to clear trails for the proposed new slides.

Knee-deep snow made the work arduous, but by the time aching muscles forced a halt, a considerable area had been cleared. The Price skiers were aided by several residents of Clear Creek, who have evidenced interest in the development of the site.

This week-end it is planned to begin work on a tow and if plans are successful it is hoped to have it in operation before the holidays.

This week the Coal Mountain Ski club is beginning a membership drive which is intended to raise funds for the completion of the tow and other work on the trails. It is planned to have skiing films available at a meeting in the near future to aid local novices in mastering control of their skis.

Those who put in last Sunday working on the tail included the following: Hubert Hreinson, Shep Olsen, the Walkington brothers, Pres. Summerhays, Lynn Goetzman, Larry Malaska, Bud McIntire, Paul Hreinson, Keith Leavitt, Fuzzy Wiseman, Ivor Koski and John Vlavovich.

Plans for ski meet in March in Final Stage

Plans for the Centennial Ski Meet to be held at Clear Creek on March 9 are nearing completion, according to Pres. Summerhays, centennial sports chairman, and invitations to participate have been sent to all ski clubs in the state. A team from the University of Utah has already signified its intention of entering the meet, Mr. Summerhays stated.

This meet, the first of its kind to be held in Carbon county, is being sponsored jointly by the county centennial committee and the Coal Mountain Ski club and is indicative of the increased interest in this sport that has been developed in the county this winter.

In preparation for the meet, the Intermountain Amateur Ski Association will send a man to the area to stake out the respective courses and events will consist of slalom and down hill events.

In addition, Mr. Summerhays reported that work will go forward on lengthening the runs before the tournament.

Another event planned is a huge banquet following the meet to be held at Clear Creek for visiting skiers.

Ski Club Plans Lighting Run at Clear Creek

More elaborate plans to make the Clear Creek ski run one of the best in the state were announced this week by the Coal Mountain Ski club. These plans call for the installation of lights along the course to make night skiing possible, and it was reported that these would probably be installed by Saturday night. In addition, to make for more spectacular night skiing, arrangements have been made to obtain flares which can be carried by the skiers as they come down the hill which will result in an interesting display for spectators.

Pres. Summerhays, chairman of the Carbon county centennial committee's sports committee, announced today that a large number of entries from throughout the state have been received for the ski tournament which will be held at the Clear Creek run on March 9.

Carbon Centennial Ski Meet Set For

Saturday and Sunday

Men's and women's downhill, slalom and novelty races will be last day feature.

Carbon county's first big centennial sports event of the year will take place this coming Saturday and Sunday, March 8 and 9, at Clear Creek when several skiers from out of the county and county ski enthusiasts will meet to vie for trophies in downhill, slalom and novelty race events. This big event, the first of its kind ever held in Carbon county, is under the sponsorship of the Coal Mountain Ski club with the able cooperation of the Utah Fuel Company, operators of the Clear Creek mine.

According to Tournament Chairman Pres. L. Summerhays, the skiers will get together Saturday evening at 8:00 p.m. for some novelty night skiing on the newly lighted course. The Utah Fuel company has completed the installation of lights and in addition, flares will be carried by the skiers as they race down the hill. This combination is expected to result in a very attractive outdoor display.

Following this, at 10:00 o'clock the skiers will meet at the Clear Creek boarding house for breakfast and at noon a meeting of the officials and participants will be held at which time drawings will be held for contest places.

The actual contest events will begin at 1:00 p.m. with women's downhill races. These will be followed by men's downhill races. Slalom events for both men and women will follow and the contest will be concluded with a novelty race. Two runs will be allowed in each event.

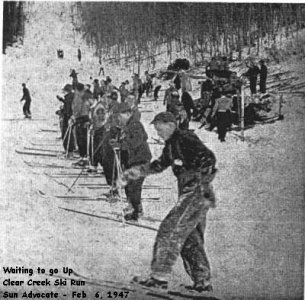

Special Train Is Scheduled to Ski Run Next Sunday

The first special train for ski enthusiasts in the history of the sport in this section has arranged by the Coal Mountain Ski club to transport 200 skiers from Helper to Clear Creek, site of the newly completed ski run, next Sunday, March 9.

Efforts are now being made to assure a guarantee of 200 persons necessary for the railroad to make the run. The train will leave Helper at 9:00 a.m. stopping briefly at Castle Gate and arrive at Clear Creek at 12:10 p.m. Return trip will start about 5:00 p.m.

Those who desire to go are advised to furnish their own lunch. Total fare for the round trip is $1.82.

Carbon's First Ski Meet Called complete success

Run off under almost perfect snow and weather conditions, the Coal Mountain Ski club's first annual ski meet Sunday was pronounced an unqualified success by some thirty participants and several hundred spectators.

As was expected, most honors went to out of county contestants. Two East High School students, Gordon Woolley and Peg Vorse, copped first places in the men's and women's events, respectively, with total times of 79.8 and 57.3 seconds. Only two events were run by the women.

Third place went to Carbon county's Keith Leavitt, who negotiated the two down mountain runs and the slalom course in the total time of 85.5 seconds, for the fourth best time of the day. Earl Miller, Provo ski instructor, who was running open, made second best time of 84.6.

Considering that local skiers have had a suitable course for only a few months, their performances against some of the best skiers in the state of Utah was considered extremely creditable. Seven skiers from the Coal Mountain club entered the various events, some of whom had never skied before this winter. This was particularly true of those from Clear Creek, who have developed into the most enthusiastic ski fans.

Results of the meet, in total times, are as follows:

Gordon Woolly, East High, Salt Lake, 79.8; Gene Smith, Sanpete, 82.3; Earl Miller, Provo, 84.6; Keith Leavitt, Price, 85.5; Delmonte Johnson, Provo, 87.1; Boyd Henrie, Sanpete, 87.2; Boyd Smith, Salt Lake, 87.4; Don Cook, Salt Lake, 87.4; Phil Snelgrove, Provo, 92.7; Bud McIntire, Price, 94; Verl O'Brien, Salt Lake, 97; Ben Fullmer, Salt Lake 104.4; Joe Hilbers, Provo, 112.5; John Wells, Salt Lake, 114.7; and Boyd Bunnel, Carbon, 115.

Contestants entering only the downhill events, and thus not qualified for the trophies, included; Jean Randall, Provo, 157.1; Irma Stirman, 78.8; Richard Watkins, U. of U., 91.4; Robert Bentley, U. of U. 22.3; George Scharman, Salt Lake, 49.4; William Thomas, Carbon, 61.9; Iver Koski, Carbon, 64.3; Lynn Goetzman, Carbon, 86.6; Jack Malaska, Carbon, 68.2.

Memories of the Clear Creek Ski Resort

Clark Hunt writes:

I learned to ski from my Uncle John Burton. John and Edna lived in Salt Lake in the late 1930's and early 1940's. When they lived in Salt Lake, John became a member of the amateur ski club led by Alf Engen that created Alta. As I remember Uncle John's discussions, Alta was a result of the club formed by Alf Engen that lobbied to create a ski facility at Alta.

When John and Edna moved back to Carbon County in the late 1940's, John helped to create the skiing hill at Clear Creek. As I was told, a large electric motor was moved out of the Clear Creek mine and used to power a "T-Bar" ski lift. The "Ski-Hill" was found beyond the left fork of the road when entering Clear Creek near the mine tipple. There was also a "Skier's cabin" at the right bottom of the ski hill. I remember being told that light snows in the late '40s and early 50's coupled with eventual failure of the ski lift electric motor closed the Clear Creek Ski Resort.

In the mid-50's, Uncle John Burton was an active member of the Carbon County Ski Club. The Clear Creek ski-hill was closed in about 1952. Uncle John Burton helped to organize the County Ski Club and seek interested parties in maintaining the equipment. This included a portable rope tow system used on the site after the mine equipment had been abandoned.

Bill Llewelyn writes:

My name is Bill Llewelyn Jr. I was born and raised in Clear Creek and have a lot off memories of the origination of the ski tow and cook shack or warming house at the bottom of the tow.

The first ski tow was a rope tow that was given or acquired from the Brighton ski lift area up Big Cottonwood Canyon.

The skier you see in overalls is my father William (Bill) Aurther Llewelyn. He had a great deal to do with helping build the rope tow and later the T-Bar as did just about everyone in the town of Clear Creek.

My mother along with a good many of the other ladies use to work in the cook shack on Saturdays and Sundays.

As young kids, if the week-end was busy we would not be allowed to ski so the older out of town people could ski. After all they paid their dollar or (was it more) to ski but that was alright with us kids because we could always talk one of our dads into going up to the lift in the evenings after work and running it for us. That is after they put lights in.

It was a great source of income for the town and I am sure it contributed to the welfare fund in which we would reap the benefit by having movies on Sunday and Wednesday nights.

I have a lot of great memories about my youth in Clear Creek. Mostly the thing I remember the most though is how everyone up there seemed like family. I still know several people that live or spend the summers in Clear Creek.

Wilfred Peters writes:

I read the article Skiing in Carbon County and being a Skiing Teenager there at that time is brought back good memories. Pres. Summerhays, his wife and two sons stayed in the house next door during a couple summer months while the Carbon Football team stayed in the dorm and practiced on the baseball diamond.

The Ski meet had a night event. They had a individual with a large battery in a back pack with lights attached to him making him appear as a large man in a top hat and cane. He skied back and forth down the slope. In front and back of him were skiers with torches. We teenagers got to each carry a torch. I was 13. My two skiing buddies, Thomas Dyches 12, and Duane Jones 12 each carried a torch. There were also youth races set up during the day as I remember Duane was usually the winner and I usually brought up the tail.

THE GENEVA COAL MINE AT HORSE CANYON, UTAH

DONALD P. BUTLER

FEBRUARY 1961

FEBRUARY 1961

PREFACE

This paper is a general report of the complete operation of the production of coal at the Geneva Coal Mine at Horse Canyon, Utah, which is the primary source of coal for the Geneva Steel Plant in Provo, Utah. The mine is located on the border of Carbon and Emery Counties and is about 10 miles south of Dragerton, Utah.

Most of my sources of information were obtained from the Mining Engineering Department and the Mine Inspection Department at the main office of the Geneva Mine, which is located in Dragerton. They also furnished the many photographs of the mine, which appear throughout the paper. I was granted permission to visit the mine and my father guided me through during an actual working shift. While I was there, I witnessed all the processes and operations which are carried out to produce the coal.

I have added a glossary to the paper which includes many common coal mining terms that may not be clear to the reader.

THE HISTORY OF COAL

The story of coal in eastern Utah begins about one and one half million centuries ago.(1) Coal, which is of organic origin, was formed from the remains of living things such as trees, herbs, shrubs, vines, and other plant material which flourished on the earth long before the time of man. This mild, moist period is often referred to as the Carboniferous Age. Coal is actually the fossilized material which was buried in layers by changes in the surface of the earth. These layers, or seams, were formed when water came into this vegetation and gradually formed new soil at the bottom. This process continued for a long period of time until the vegetation was decayed and buried, forming a coal seam. The character of the coal depends upon the nature of the original plants, the type of decay which took place, and the time involved during burial and formation.(2)

Most of the world's high-grade coal was formed from 150 to 280 million years ago during the Carboniferous Age. Low grade coal was formed later, principally during the Cretaceous Period and the Eocene Period. Coal is still being formed in small quantities today, but hundreds of thousands of years are required to complete the process.(3) There are two main classes of coal: Bituminous, which is soft coal, and Anthracite, which is hard coal. Bituminous is more plentiful and is used much more extensively than Anthracite.

Coal was known of and used as a fuel before the beginning of the Christian Era. One of the earliest records of the utilization of coal dates back to the 4th Century B. C., when the local smiths in Greece used what they called "fossil substances," or coal, as their fuel.

When coal was first discovered, it was used primarily as a fuel, and was not mined extensively. When the iron industry started, however, it brought about a greater demand for coal, and the mining industry expanded quickly. The extensive full scale mining of coal was first carried on in Great Britain during the 13th Century. (4)

THE HISTORY OF THE GENEVA MINE

As World War II was approaching, the United States Government launched a program to increase the steel production capacity of the nation. After the Pearl Harbor Attack, the policy of establishing steel mills near the sources of raw materials and away from threatening bomb areas was adopted. The Geneva Steel Plant in Provo, Utah was one of these plants, and it necessitated the opening of more coal mines. This was the reason for the establishment of the Geneva Mine at Horse Canyon.(5)

The mine is located at Horse Canyon, Utah, which is on the eastern rim of Castle Valley. It is 35 miles southeast of Price, Utah, and approximately 160 miles southeast of Salt Lake City.(6) It is located 128 rail miles southeast of the Geneva Plant in Provo.(7)

The construction of the mine was started in the Spring of 1942, and the actual underground work in the coal seam began in the following October. The main development openings were driven while the surface plant was still under construction. The coal which was produced at this time was treated by a small capacity temporary tipple. A 1300 foot rock tunnel was driven to the coal seam, and a rotary dumping station was installed.

The mine was developed and organized under the general direction of Mr. F. V. Hicks, the first general superintendent.(8)

In December, 1943, the Geneva Steel Company began operating the mine for the Defense Plant Corporation, which was a United States Government Agency. On June 16, 1946, the mine was purchased from the War Assets Administration by the United States Steel Corporation, and was operated by the Geneva Steel Company until January 1, 1952, when the Geneva Company became a part of the Columbia-Geneva Steel Division.(9)

Figure 1. The surface plant at the mine. The mine portals are located at the top left of the picture.

Just a few years after its beginning, the Horse Canyon mine was, and still is, one of the largest producing coal mines west of the Mississippi River. The mine has produced approximately 5000 tons per day on a two 8 hour shift basis. The total number of underground employees is 458.(10) In 1957, 490,000,000 tons of Bituminous coal were produced in the United States.(11) The Geneva Mine at Horse Canyon produced approximately 1,700,000 tons during the same year.(12) Thus, in 1957, the Geneva Mine produced about 0.35 %, or 1/288 of the Bituminous coal produced in the United States.

THE COAL SEAMS AT HORSE CANYON

The seams at Horse Canyon are found in the Bookcliffs, a mountain range on the eastern rim of Castle Valley. They dip eastward at an incline, or pitch, of 12.5%.. This means that the pitch of the slope lowers approximately 12 ' feet for every 100 feet as it progresses eastward.

The rock layers surrounding the coal seams are mainly sandstone and they vary from a few feet to as much as 50 feet in thickness. Shale is very prevalent and the sandstone beds are usually interbedded with sandy shales. Some limestone beds are also present. The depth of cover over the mined areas varies from 300 feet to approximately 2,900 feet with an average of more than 1,000 feet.

Figure 2. A typical formation section of the coal seams of the Horse Canyon area. It illustrates the incline of the seam, the formation of the seams, and a typical fault.

The coal seam that is mined is called the Lower Sunnyside Seam and it varies from 7 to 16 feet in thickness. The elevation of this seam is 6355 feet at the mine portal. The seam is relatively free from bone or partings except in the extreme southeast and northern sections of the mine. Beneath the seam is a layer of sandstone that forms a shelf along the outcrop of the coal seam. Above the seam is a bed of thin sandstone and sandy shale that averages 3 feet in total thickness, and over this parting lies the Upper Sunnyside Seam which is about 3 feet thick. This upper seam, often called the rider seam, is not mined at the present time.

The coal that is mined is hard, sub-bituminous, high volatile coking coal, which has a low sulfur and ash content.(13)

The occurrence of faults in the mine is quite frequent. Faults, in geology, are fractures which move the layers of the earth's crust. One of the masses of earth is uplifted and is called the upthrow, and the other is depressed and called the downthrow. The amount of displacement varies considerably.(14)

Most faults in the mine slope from east to west. Most of them are less than 15 feet in displacement, but there is one of 55 feet and one of about 100 feet throw. The dips of the faults are quite steep, varying from 50 degrees to as much as 70 degrees from the horizontal. The faults seem to occur at about 2000 foot intervals in the southern portion of the mine, but in the northern section, the faulting is irregular, excepting one large normal fault.

The fault system and the pitch of the seam are the main factors controlling the general layout of the mine. The mine consists of one set of east-west slope entries, and three sets of north-south entries, extending along the strike and from the slope entries at intervals of one-half mile each. The north-south entries are called lst, 2nd, and 3rd levels, beginning at the eastern, or highest one.

Openings have been made into the seam on both sides of the canyon, about one-half mile from the mouth of the canyon. The main entries to the north have been driven approximately 3,100 feet to a major fault zone, which displaces about 40 feet downthrow. This fault has been penetrated and development has continued for another 3,500 feet to a major fault zone that separates the mine from the Columbia Mine, another Geneva mine. The South mine has been extended approximately two miles to the southern boundary of the mine. Three major fault zones were driven through on the South side. The main slope entries are presently approximately 8,000 feet down the pitch.(15)

THE PRODUCTION OF THE COAL

Many rapid advances in coal mining machinery have brought modern mining equipment to Horse Canyon. At the present time, there are two types of mining districts: conventional trackless mining units and continuous mining units. These units will be explained later.

The general mining plans call for room and pillar mining layouts. The actual mining is accomplished by first mining the upper part of the seam and bolting the roof; (roof bolting will be explained in the next chapter) then, when retreating, the pillars and the lower part of the seam are taken. This procedure is called bench mining. Many other modifications are made to conform to various faults, irregular seam pitch, and other natural conditions. The coal is initially blocked out for mining by primary slope and strike development. The boundaries of the mining districts are established by this primary development and by major fault zones. Secondary development has standardized to where it is similar in districts using either track or conveyor belt haulage.(16)

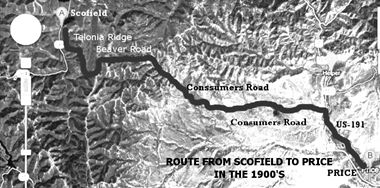

While the railroad went from Price to Colton to Scofield, the primary pedestrian route to Scofield, did not go up Price Canyon, it was a wagon road that went by way of Consumers and Beaver Roads and down Telonia Ridge past the UP mine into Scofield (about 27 miles as shown in the photo). Maybe a Model T Ford could manage the route but it was mostly for horse drawn wagons.

While the railroad went from Price to Colton to Scofield, the primary pedestrian route to Scofield, did not go up Price Canyon, it was a wagon road that went by way of Consumers and Beaver Roads and down Telonia Ridge past the UP mine into Scofield (about 27 miles as shown in the photo). Maybe a Model T Ford could manage the route but it was mostly for horse drawn wagons.